Unlocking Retail Success: Leveraging 3PL Solutions for Seamless Fulfillment

Imagine you’re a customer who ordered something from an online store, and unfortunately, your package was either delayed, lost, or arrived damaged.

Very disappointing, right?

According to the survey, the estimated time of delivery holds significant influence over 68% of customers’ purchasing decisions. And 37% of customers say that they will never shop with a retailer again after a bad delivery experience.

An efficient and well-developed order fulfillment process makes it easy to prevent that outcome for your e-commerce business.

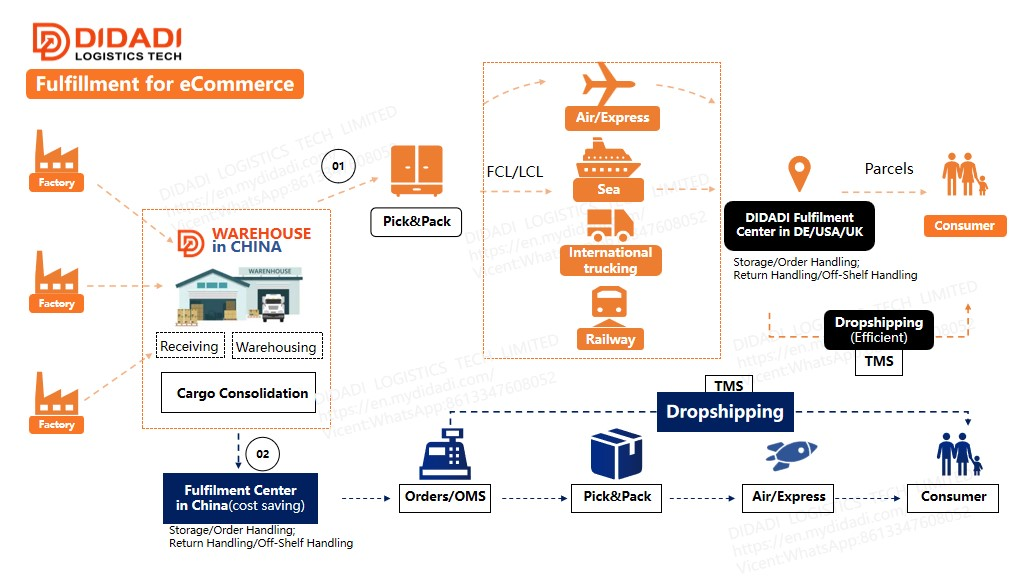

Order fulfillment refers to the entire process of receiving, processing, and delivering customer orders. It involves various activities, such as order processing, inventory management, warehousing, picking, packing, shipping, and managing returns.

Efficient order fulfillment is crucial for customer satisfaction, brand reputation, and overall business success. It requires careful coordination of inventory management, warehouse operations, logistics, and customer service.

DIDADI’s Warehouse

With the rise of e-commerce and the increasing demands of customers for fast and accurate order fulfillment, businesses are focusing on optimizing their fulfillment processes and often leveraging the expertise of third-party logistics providers (3PLs).

The order fulfillment process in a 3PL’s fulfillment center consists of several interconnected steps that ensure the smooth handling of customer orders. Here’s an overview:

Receiving and Inventory Management

The order fulfillment process in a 3PL’s fulfillment center begins with the receipt of inventory. Each incoming shipment is carefully inspected, and inventory records are updated to reflect the new stock.

This stage involves verifying the quantity and quality of the received products, conducting quality checks if necessary, and organizing them within the warehouse.

Storage and Organization

Once the products are received, they are assigned a designated storage location within the fulfillment center.

Order Processing and Management

When a customer places an order, the 3PL’s order management system comes into play. The order is transmitted electronically from the client’s system to the fulfillment center’s system.

At this stage, the order details are validated, including product selection, quantities, and any special instructions or customization requirements. The order is then prioritized based on factors like shipping method, service level agreements, and delivery deadlines.

Picking and Packing

Shipping and Carrier Selection

Once the order is packed, the 3PL selects the most suitable shipping carrier based on factors like destination, delivery speed, and cost. The package is prepared for shipping, including label printing, documentation, and manifest generation.

Return Management and Reverse Logistics

In the event of product returns or exchanges, 3PLs also handle the reverse logistics process. They manage the return authorization, coordinate the shipment back to the fulfillment center, and inspect the returned products.

Proper procedures for restocking or refurbishing returned items are implemented, and updated inventory records reflect the changes.

There are different order fulfillment models that businesses can adopt based on their specific needs:

In-House Fulfillment Model

The in-house fulfillment model involves businesses managing the entire order fulfillment process internally, from receiving orders to shipping the products.

This approach offers complete control over the process, allowing businesses to maintain quality standards, customization, and branding.

Key considerations for in-house fulfillment include infrastructure, warehousing space, labor, technology, and inventory management systems. While this model offers control, it can be capital-intensive and time-consuming, particularly for small to medium-sized enterprises.

Dropshipping Model

Dropshipping has gained popularity in recent years, especially among e-commerce businesses. In this model, the retailer partners with suppliers who handle the inventory storage, packaging, and shipment of products directly to customers. The retailer focuses on marketing, sales, and customer service.

Dropshipping eliminates the need for upfront inventory investment, reduces operational complexities, and enables businesses to offer a wide range of products. However, it may lead to lower profit margins and limited control over inventory and shipping times.

Third-Party Logistics (3PL) Model

The 3PL model involves outsourcing the entire order fulfillment process to a specialized third-party logistics provider. These providers have extensive expertise, infrastructure, and networks to manage warehousing, inventory, order processing, packaging, and shipping.

By leveraging the capabilities of 3PL providers, end-to-end businesses can reduce operational costs, benefit from scalability, and focus on core competencies like marketing and product development.

DIDADI’s Fulfillment Process

Hybrid Fulfillment Model

A hybrid fulfillment model combines elements of in-house fulfillment and outsourcing to achieve a tailored approach. Businesses can choose to handle some aspects internally, such as inventory management and customer service, while outsourcing warehousing and shipping to a 3PL provider.

This model offers flexibility, allowing businesses to adapt to changing needs, control costs, and maintain customer satisfaction. However, it requires effective coordination between internal teams and external partners to ensure a seamless order fulfillment experience.

Third-party logistics providers play a vital role in streamlining the order fulfillment process. These specialized companies offer a range of services tailored to meet the unique needs of businesses.

By partnering with a 3PL provider, companies can benefit from their expertise, infrastructure, and network of resources, leading to several advantages:

Scalability

3PL providers have the ability to scale operations up or down based on direct-to-consumer(DTC) retailers‘ needs. Whether it’s handling seasonal fluctuations or expanding into new markets, 3PLs offer the flexibility to adapt quickly, ensuring a seamless fulfillment process.

Cost Efficiency

Outsourcing order fulfillment to a 3PL can often result in significant cost savings. Instead of investing in warehouse space, equipment, and labor, businesses can leverage the 3PL’s existing resources, reducing overhead expenses and improving overall profitability.

Expertise and Technology

3PL providers possess extensive knowledge and experience in logistics management. They are equipped with advanced technologies such as warehouse management systems, inventory tracking software, and order processing systems.

This expertise and technology enable faster, more accurate order fulfillment, minimizing errors and enhancing customer satisfaction.

Expanded Reach

3PL providers often have a widespread network of distribution centers and transportation resources. This allows businesses to access new markets, both domestically and internationally, without the need for significant infrastructure investments. By leveraging the 3PL’s network, companies can tap into a wider customer base and increase their market presence.

Focus on Core Competencies

Outsourcing order fulfillment to a 3PL frees up valuable time and resources for businesses to focus on their core competencies, such as product development, marketing, and customer service. This strategic allocation of resources can lead to improved overall business performance and growth.

DIDADI is a trusted and leading 3PL provider that offers comprehensive order fulfillment solutions for e-commerce businesses. We specialize in warehousing, inventory management, picking, packing, shipping, and returns management.

With advanced technology, robust infrastructure, and a customer-centric approach, DIDADI ensures accurate and timely order fulfillment.

We also provide scalable solutions that cater to businesses of all sizes, allowing seamless expansion as your operations grow. DIDADI’s commitment to transparency, performance metrics, and exceptional customer service makes them an ideal partner for your order fulfillment needs.

Recommended Reading