3PL Inventory Management: Every Online Business Needs to Know

Inventory management is a critical aspect of running a successful business, regardless of its size or industry. It refers to the process of overseeing and controlling a company’s inventory, from procurement to storage, tracking, and order fulfillment.

Approximately 83% of online shoppers expect real-time visibility into product availability. And businesses with effective inventory managing achieve a 96% stock accuracy rate and an 8% increase in gross margin.

In this article, we will delve into the significance of inventory management, the situations that call for an inventory management system, and how to find the best strategy for your e-commerce inventory managing.

Inventory management encompasses all activities related to the acquisition, storage, tracking, and fulfillment of a company’s products.

It involves maintaining accurate records of inventory levels, forecasting demand, and making informed decisions to ensure an optimal balance between supply and demand.

Inventory management systems often leverage technology, such as barcode scanning, RFID (Radio-Frequency Identification), and software, to streamline and automate these processes.

Effective inventory management plays a crucial role in the success of any business. Here are several reasons why it is essential:

Meeting Customer Demand

One of the primary reasons inventory managing is important is to meet customer demand. By having the right products available when customers need them, businesses can enhance customer satisfaction and loyalty.

Managing inventory effectively ensures that end-to-end e-commerce have sufficient stock levels to fulfill customer orders promptly, avoiding stockouts or backorders.

It enables businesses to provide reliable and efficient customer service, which is essential for building a strong customer base and gaining a competitive edge.

Cost Efficiency

Inventory represents a significant investment for any business. Effective inventory managing allows companies to strike the right balance between having enough stock to meet customer demand and avoiding excessive inventory carrying costs.

By accurately forecasting demand, optimizing order quantities, and reducing carrying costs such as storage, insurance, and obsolescence, businesses can minimize their stock holding costs.

This helps in maximizing profitability by avoiding overstocking and reducing the risk of deadstock or inventory shrinkage.

Streamlining Supply Chain Operations

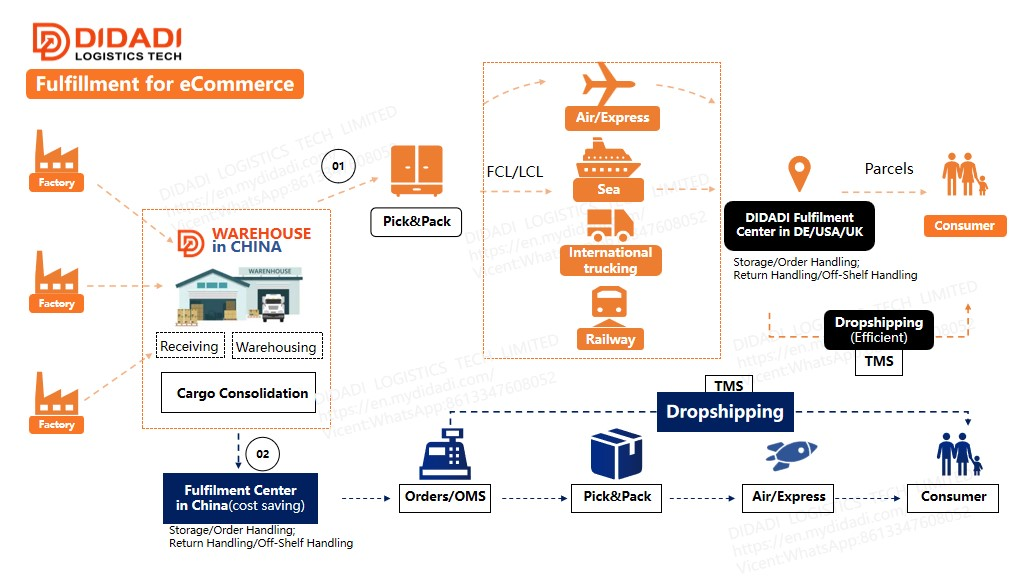

Inventory management is closely tied to supply chain management. It ensures the smooth flow of goods from suppliers to manufacturers, distributors, and ultimately to customers.

By implementing efficient inventory management practices, businesses like Direct-to-consumer (DTC) brands can reduce lead times, minimize order processing delays, and improve overall supply chain efficiency. This results in cost savings, increased operational agility, and better responsiveness to market fluctuations.

Optimizing Production and Manufacturing Processes

For businesses involved in production or manufacturing, inventory management is essential for optimizing these processes.

By accurately tracking raw materials and work-in-progress inventory levels, companies can ensure they have the necessary inputs to maintain production schedules.

Effective inventory management helps prevent production delays caused by material shortages or stockouts, leading to improved production efficiency and on-time delivery of finished goods.

Demand Forecasting and Inventory Planning

Inventory management involves analyzing historical sales data, market trends, and customer demand patterns to forecast future demand accurately. This allows businesses to plan their inventory levels accordingly, reducing the risk of excess inventory or stockouts.

By aligning inventory levels with expected demand, companies can make informed purchasing decisions, minimize holding costs, and optimize working capital.

Implementing an inventory management system becomes necessary in various situations, including:

Rapid Growth

As businesses expand, their inventory management requirements become more complex. An inventory management system can help handle increased demand, multiple locations, and a larger product portfolio efficiently.

DIDADI operates warehouses across the world. With DIDADI, you have the flexibility to distribute your inventory across multiple fulfillment centers strategically, ensuring efficient order processing based on your customers’ locations.

Seasonal Demand Requires an Inventory Management

Businesses that experience seasonal fluctuations in demand require an inventory management system to forecast demand accurately, plan production and procurement, and optimize inventory levels during peak seasons and off-peak seasons.

Multiple Sales Channels

Companies that sell through multiple channels, such as brick-and-mortar stores, e-commerce platforms, and wholesale distribution, need an inventory management system to synchronize inventory across channels, prevent overselling, and maintain accurate stock levels.

Costly Stockouts or Overstocks

Experiencing frequent stockouts leads to lost sales and dissatisfied customers, while overstocks tie up capital and increase storage costs. An inventory management system helps prevent these issues by providing real-time visibility into stock levels and enabling proactive replenishment.

Outsourcing warehousing and inventory management to a third-party logistics provider (3PL) offers several advantages for businesses. Here’s why you should consider it:

Expertise and Scalability

3PLs specialize in logistics and supply chain management:

The expertise to efficiently handle warehousing by using warehouse management system(WMS).

The resources to deal with inventory management and distribution operations.

Scale their services as your business grows.

Ensuring you have the necessary infrastructure and capabilities to meet increasing demand.

Cost Savings

This eliminates the need for investing in additional facilities, technology, and personnel, reducing overall expenses.

Focus on Core Competencies

Outsourcing non-core activities like warehousing and inventory management allows businesses to focus on their core competencies, such as product development, marketing, and customer service. This promotes overall business growth and enhances competitiveness.

Enhanced Flexibility and Adaptability

3PLs offer flexibility in managing inventory fluctuations, allowing businesses to scale up or down as needed. They can also adapt to changing market conditions, such as entering new markets or launching new products, ensuring smooth logistics operations.

Experience and Expertise

Look for 3PLs with a proven track record in handling inventory management and logistics for businesses in your industry. Their expertise in managing similar products, distribution channels, and industry-specific challenges will be invaluable.

Technology and Systems

Assess the technology and systems the 3PL utilizes for inventory management. Ensure they have robust inventory tracking and reporting capabilities, as well as integration options with your existing systems, such as your e-commerce platform or ERP (Enterprise Resource Planning) software.

Scalability and Flexibility

Evaluate the 3PL’s ability to scale operations and accommodate your business’s future growth. Consider their network of facilities, geographical reach, and ability to handle peak season demands or unexpected surges in orders.

Service Level Agreements (SLAs) and Metrics

Clearly define the performance metrics and service level agreements with the 3PL. This includes parameters such as order accuracy, on-time delivery, inventory accuracy, and responsiveness to inquiries or issues.

Recommended Reading