Reliability as a Market Position: How DIDADI Built Europe’s Most Predictable FBA Delivery Network Over 16 Years

In global trade today, uncertainty is no longer an exception — it is the baseline.

From port congestion and capacity shortages to labor disruptions and regulatory changes, international logistics has become increasingly fragile. For cross-border eCommerce sellers, especially those operating within Amazon’s tightly structured fulfillment system, logistics is no longer just a cost line. It is a core operational risk factor.

Traffic, branding, and advertising can generate demand.

But only one thing determines whether that demand turns into sustainable growth:

Can inventory arrive on time, consistently, and as planned?

For Amazon sellers, logistics performance directly affects three fundamentals:

Cash flow velocity

Listing availability and ranking stability

Inventory Performance Index (IPI) and storage capacity

In this context, delivery speed alone is not enough. What sellers truly need is predictable transit time. A shipment that arrives five days early or ten days late creates the same problem: broken planning.

This is why on-time delivery rate, rather than theoretical transit time, has become the most meaningful indicator of a logistics provider’s real execution capability.

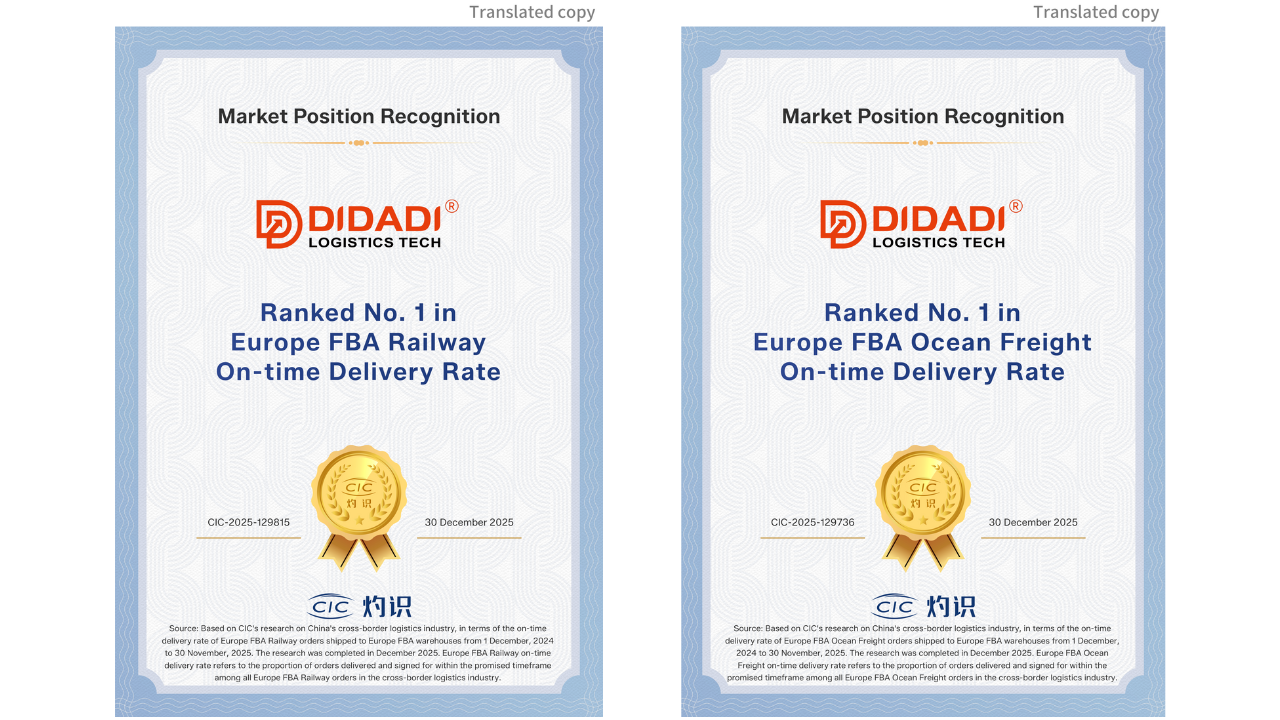

Following extensive market research and data validation, CIC Consulting (China Insights Consultancy) — an internationally recognized independent consulting and research firm — officially certified DIDADI Logistics Tech as:

Ranked No. 1 in Europe FBA Ocean Freight On-time Delivery Rate

Ranked No. 1 in Europe FBA Railway On-time Delivery Rate

This certification reflects sustained operational performance across the market, not isolated cases or self-reported data. It confirms DIDADI’s ability to deliver cargo to European Amazon FBA warehouses within committed timelines, at scale, and over long periods of time.

For sellers, this recognition represents one thing above all else: reduced uncertainty.

Achieving consistent on-time performance in cross-border logistics is not a result of tactical adjustments. It is the outcome of long-term structural capability building.

Over the past 16 years, DIDADI has operated through multiple global supply chain cycles — from rapid expansion to severe disruption. This experience shaped a clear understanding: delays are inevitable; uncontrolled delays are not.

(DIDADI Europe rail service covered by Guangdong News Broadcast)

International logistics is vulnerable at every stage: vessel rollovers, port congestion, rail capacity limits, strikes, and weather disruptions. The difference between stability and chaos often comes down to who controls capacity.

Priority Space Allocation

DIDADI maintains long-standing strategic partnerships with major ocean carriers and international rail operators. These relationships translate into first-tier booking access and priority allocation, especially during peak seasons when capacity becomes scarce.

This allows DIDADI to secure containers when others cannot — not by paying spot premiums, but through trust built over years of consistent volume and operational reliability.

Structural Risk Resilience

Years of exposure to supply chain disruptions enabled DIDADI to build a proactive risk response system. Instead of reacting after delays occur, alternative routing, mode switching, and capacity reallocation plans are prepared in advance — allowing shipments to remain in motion even under adverse conditions.

On-time delivery is not achieved by chance. It is engineered through process discipline.

Since 2022, DIDADI has conducted a full-scale upgrade of its end-to-end Standard Operating Procedures, breaking the international logistics chain into dozens of tightly controlled operational nodes:

From origin pickup and container loading, to customs declaration, linehaul transport, clearance, port drayage, and final delivery into Amazon FBA.

Status-Based Visibility, Not Just Tracking

Each shipment is monitored through real-time status indicators. Internal systems automatically flag exceptions when any node exceeds predefined time thresholds, prompting immediate intervention by dedicated operational teams.

This allows issues to be addressed before they cascade into major delays.

Compliance as a Time Protection Strategy

High inspection rates are one of the most common causes of unpredictable delays. DIDADI implements strict pre-shipment compliance checks and deliberately avoids mixing borderline or non-compliant cargo.

While this approach means declining certain shipments, it protects compliant sellers from shared risk and preserves overall schedule reliability.

In practice, many shipments do not lose time at sea — they lose time after arrival.

Port congestion, drayage shortages, and FBA appointment backlogs often create the largest gaps between planned and actual delivery. DIDADI addresses this by investing deeply in destination operations rather than relying purely on external vendors.

Localized Operations and Dispatch Control

DIDADI operates and manages overseas warehousing and trucking resources across Europe and the United States, enabling tighter coordination and faster response to on-the-ground disruptions.

FBA Appointment and Smart Rerouting

With established delivery credentials and local carrier networks, DIDADI secures FBA appointments more efficiently. Through its Smart Reroute solution, shipments can be dynamically redirected to alternative Amazon fulfillment centers when congestion occurs — reducing inbound delays and preventing stockouts.

Multi-Modal Delivery Strategies

By combining multiple transport modes and delivery partners, DIDADI maintains flexibility in last-mile execution, adjusting routes and carriers based on real-time conditions.

All operational capability must ultimately translate into commercial value. For Amazon sellers, predictable logistics creates tangible advantages.

More Accurate Replenishment and Faster Cash Turnover

Reliable ETAs allow replenishment planning based on data, not assumptions. Safety stock can be reduced, freeing up working capital that would otherwise be locked in excess inventory and overseas storage fees.

Lower Stockout Risk and Stronger Listing Performance

Consistent inbound flow protects listings from stockouts during peak seasons. Avoiding even a single stockout can preserve ranking momentum and reduce the need for costly advertising recovery efforts.

Stable inbound processing also supports healthy IPI scores, ensuring continued access to storage capacity.

DIDADI Logistics Tech’s recognition as Top 1 in On-Time Delivery Rate is not a marketing slogan. It is the outcome of 16 years of disciplined execution across resources, systems, and destination operations.

For sellers, this translates into higher planning confidence, lower operational risk, and more sustainable growth.

In logistics, there are no shortcuts — only long-term commitment to every shipment.

DIDADI will continue to invest in certainty, helping global sellers build resilient supply chains in an increasingly unpredictable world.

Recommended Reading